The Axiom Advantage

A Computer Numerical Control (CNC) machine is a computer-controlled cutting machine used for shaping materials like wood, plastics, composites, foams, and even soft metals. It automates precision cutting, carving, drilling, and milling—allowing makers, educators, and businesses to produce accurate parts and complex designs far faster than manual tools.

At Axiom Precision, we elevate these core CNC capabilities through precision engineering, advanced software integration, and dedicated customer support—delivering industrial-grade machines that match your true power and potential.

HIGH RIGIDITY BUILD

Every Axiom CNC is engineered from the ground up with the integrity of a large industrial CNC machine—yet compact enough to fit in your shop. Our rigid steel frames, precision ball screws, and powerful spindles ensure accuracy, repeatability, and speed across every project.

MODULAR DESIGN

Your machine should grow with your craft. Axiom CNC machines support a wide range of custom accessories and upgrades—from dust collection systems to rotary and laser kits—making it easy to expand capabilities as your projects evolve.

USER-FRIENDLY OPERATION

Forget complicated setups. Axiom CNC machines feature an intuitive hand-held controller and seamless software integration with Vectric, making them accessible for beginners while powerful enough for professionals.

DEDICATED SUPPORT

From training and troubleshooting to maintenance and upgrades, our team provides direct access to CNC machine experts committed to your long-term success.

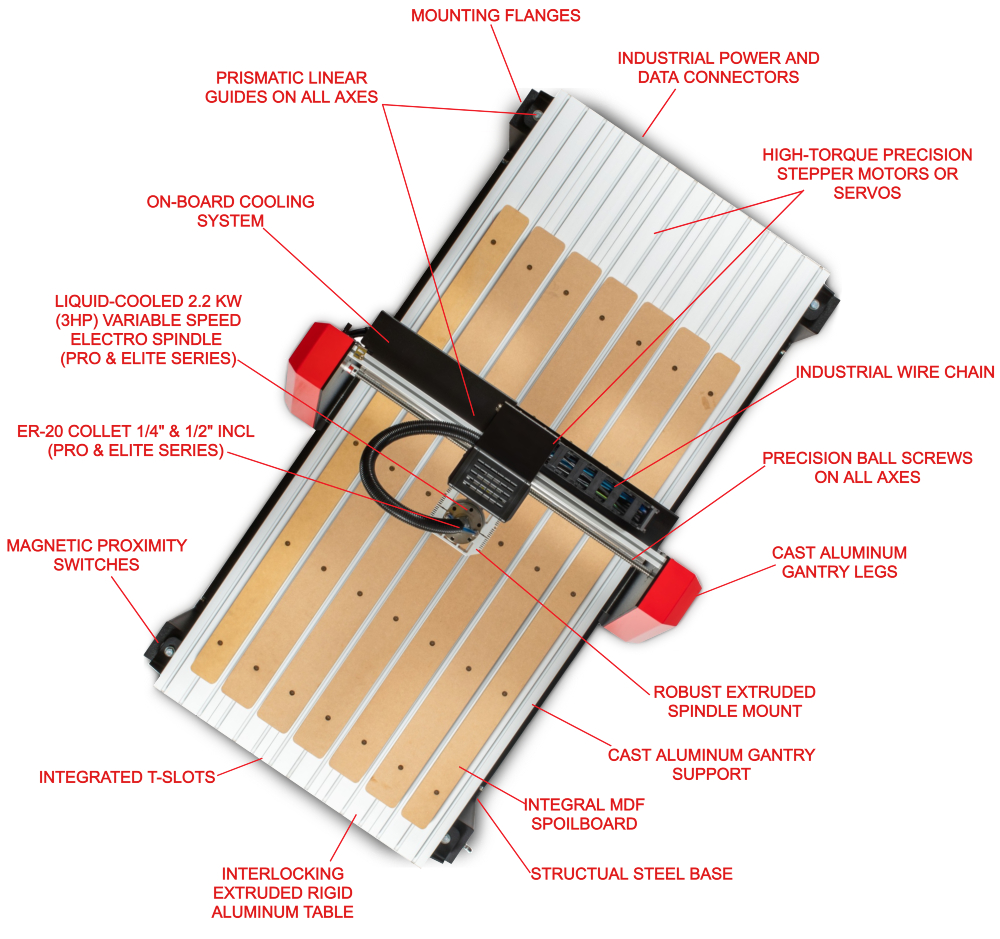

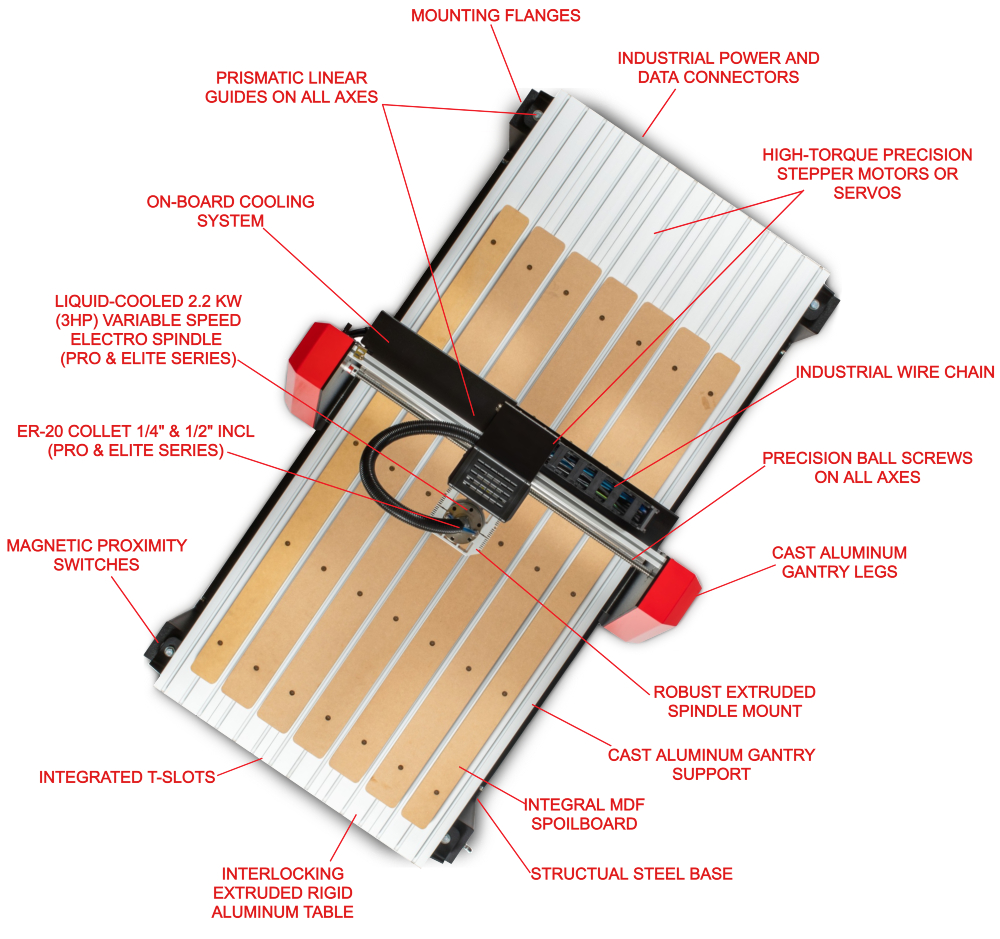

INTERLOCKING ALUMINUM TABLE

This is a seriously strong table. The massive 30mm thick extruded aluminum table provides a strong, flat surface to support your material. Integrated T-slots allow placement of hold-down clamps in any location, and a sacrificial MDF spoil board ensures that your table will always remain flat and damage free.

STRUCTURAL STEEL FRAME

Our welded, structural steel frame is heavy, rigid, and accurate. It supports the weight of your Axiom machine with ease. It also offers mounting flanges in each corner to secure your machine to an optional Axiom stand, or your work surface.

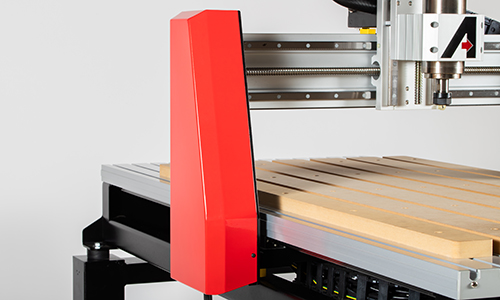

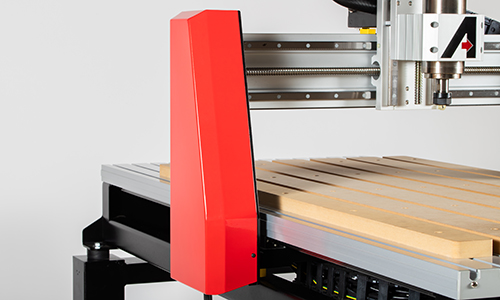

HEAVY DUTY GANTRY SUPPORTS

Heavy components traveling at a high rate of speed generate high forces of inertia. The horizontal gantry support (located beneath the table), and the vertical gantry legs take the brunt of that force. Each aluminum component is powder coated and engineered to be completely overqualified for their job.

PROXIMITY SENSORS

These magnetic sensors act as the CNC's eyes. They allow you to ‘home’ your machine so it knows where the spindle is in relation to the working envelope. Noticeably absent in many of our competitor’s machines, these sensors prevent the gantry from colliding with the stops when you run it to the extent of its travel.

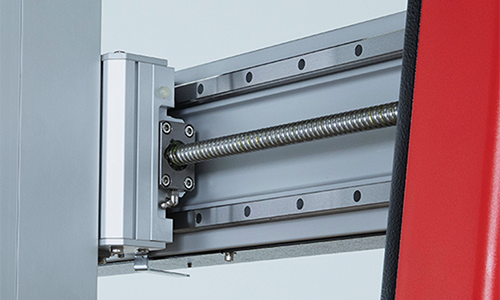

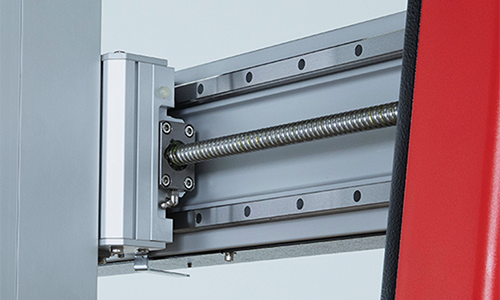

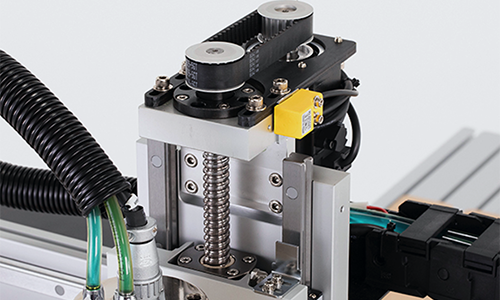

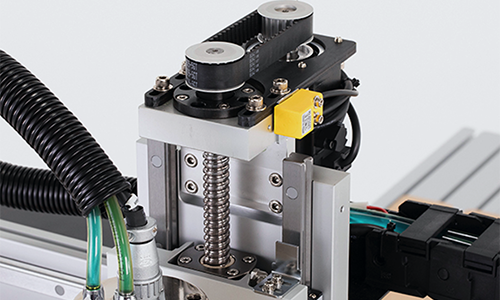

BALL-SCREWS

Motion on every axis of every Axiom machine is controlled by high-precision ball screws. These ball screws utilize recirculating ball bearings to provide close tolerance and offer unmatched accuracy. Their ability to create low internal friction, while withstanding high thrust loads at high rates of speed, is paramount to the accuracy of each Axiom CNC machine

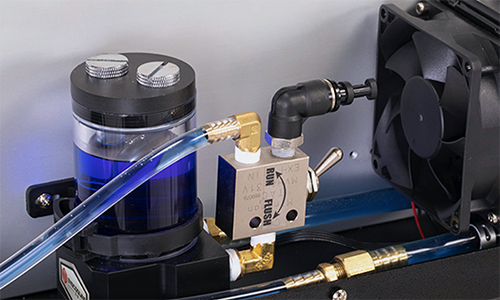

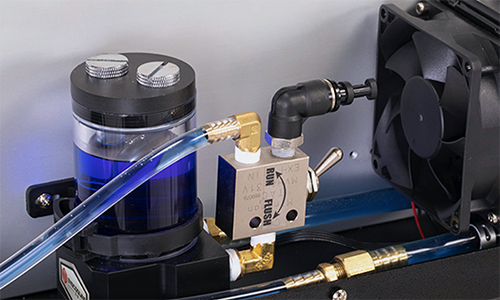

ONBOARD COOLING SYSTEM

Every Axiom Pro and Elite series machine offers a liquid-cooled electro spindle. Our innovative system replicates an automotive cooling system, where a high-volume pump pushes coolant (or antifreeze) through the electro spindle, and dissipates the heat with a radiator and fan assembly. No buckets, no hoses, no aquarium pumps. No Drama.

LINEAR GUIDWAYS

Our linear guideways utilize recirculating bearings between a prismatic rail and a bearing block. The coefficient of friction on our linear guides is only a small fraction of what is created by traditional round guides, and are able to take loads in all directions. With these features, our CNC machines achieve high precision and greatly enhanced moving accuracy.

INDUSTRIAL DSP CONTROLLER

The task of controlling your CNC machining center shouldn’t be relegated to a PC and a piece of software. Instead, we’ve integrated an industrial DSP controller with a hand-held pendant. This control solution is powerful, stable and terribly easy to operate. It’s also fully upgradable so you can install the latest firmware as needed.

CABLE TRACK CHAIN

A loose bundle of wires almost always results in abrasion, stress and broken leads. Our power and data cables, as well as cooling hoses, are contained within lightweight, flexible nylon track chains to ensure that data is never interrupted by a broken wire.

HIGH TORQUE STEPPERS & SERVOS

Depending on which machine you choose, each axis is controlled by a 57mm, NEMA 23 equivalent high-torque stepper motor, or a high precision servo motor. Each fast device is rated for high duty cycles, and will provide thousands of hours of trouble-free precision.

TOOL TOUCHOFF DEVICE

Each time you install a bit in your Axiom CNC machine, you’ll need to accurately determine the length of the new tooling. Simply slide the tool touchoff device beneath the bit, initiate the ‘measure’ command on your hand-held controller, and the bit length will automatically be determined and stored in the DSP.

INDUSTRIAL DATA CONNECTORS

The performance of your machine relies upon accurate transfer of data to the stepper motors. Every wire connecter found an an Axiom machine is of the highest quality available. Where available, we use aerospace quality components with metal body, copper terminals, and threaded locking rings.

Applications & Materials

Axiom CNC machines are versatile enough to handle a wide range of materials and industries:

- Wood & Composites — furniture, cabinetry, decorative panels.

- Plastics & Acrylics — signage, displays, custom enclosures.

- Foams — packaging, 3D models, molds.

- Soft Metals — aluminum parts, prototypes, fixtures.

Industries we serve include:

- Signage & graphics (acrylics, dimensional lettering).

- Furniture & cabinetry (hardwoods, panels, joinery).

- Prototyping & product design (plastics, aluminum).

- Education & training (schools, makerspaces, labs).

CUSTOMER TESTIMONIALS

“2 years. 2,000 hrs. Up to 20+ hrs per project. Not once has there been a problem with precision during the cut.” - Chad